About Us

Driving innovation, delivering excellence in paddy processing

Leading the way in paddy processing innovation

Our vision is to provide state-of-the-art, large-scale, smart, and fully automated food processing machinery to modernize the agro-tech industry.

We aim to deliver best-in-class parboiling and drying machinery, along with rice and granary mill installations worldwide. Our goal is to reduce wastage, improve shelf life, and create additional value for businesses, empowering customers to expand export opportunities. Through innovative machinery and advanced technical expertise, we strive to positively influence customers, industry leaders, and investors, positioning ourselves as change agents revolutionizing the agro-tech sector.

Our mission is to develop world-class food processing machinery and mills with hi-tech, smart, large-scale continuous/batch processing plants for parboiling, drying, steaming, storing, and raw paddy boiling of rice and other grains.

We aim to inspire the next generation of agro-tech businesses by delivering well-engineered, lucrative, and customizable solutions that adapt to changing needs. In a digitally connected world, we stay relevant by continually evolving to meet global industry standards. Our core values are encapsulated by I4C.

Since

Trust the experts in paddy processing.

Our Story

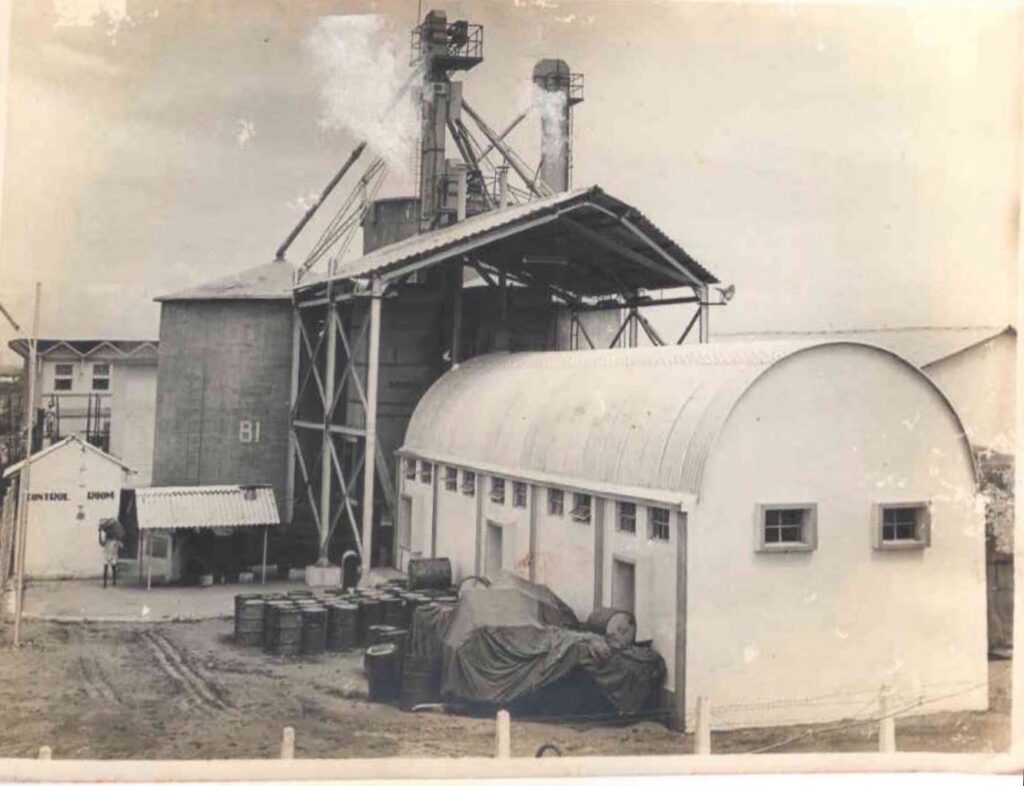

Photons Food Processing Engineers, founded in 1985 in Thanjavur—the granary of Tamil Nadu, located in the fertile Kaveri River delta—was established by seasoned professionals with extensive hands-on experience in the pre-processing of paddy and other grains, including parboiling, steaming, and drying. The founders, driven by a shared belief that modern technology could revolutionize the food processing industry, left their government careers to pioneer automation in food processing units through cutting-edge technology.

With a vision to enhance small-scale food processing businesses, Photons set out to implement state-of-the-art automation and innovation. Over the years, they have built a strong foundation of expertise, enabling them to scale up production quality, minimize breakage and losses, and ensure consistent output. Their commitment to excellence has earned them a global presence in the industry.

In 2005, as part of their expansion and for operational convenience, the factory was relocated from Thanjavur to Nidadavole, Rajahmundry, in the East Godavari District of Andhra Pradesh, India.

Our Journey

"Photons started with manual to semi-automatic systems, enhancing productivity in rice milling."

"Eco-friendly husk-fired boilers utilized rice husks

for cost-effective energy solutions."

"Batch parboiling systems were introduced,

offering improved control over soaking and steaming."

"Fully automated parboiling systems streamlined operations, reducing manual intervention."

"Photons launched precision temperature control for uniform drying and minimal grain damage."

"Photons introduced fluidized bed dryers, ensuring faster and more uniform drying."

"Energy-efficient heat recovery systems started recycling steam and energy, reducing costs."

AI-driven automation and sustainable energy solutions are leading the future of rice milling.

Advanced IoT systems provide real-time monitoring and control, optimizing efficiency.

Some of our Clients