Precision Engineering for Perfect Rice

We understand every step along the value chain from harvested paddy to packed rice

Leading the way in paddy processing innovation

Our vision is to provide state-of-the-art, large-scale, smart, and fully automated food processing machinery to modernize the agro-tech industry.

We aim to deliver best-in-class parboiling and drying machinery, along with rice and granary mill installations worldwide. Our goal is to reduce wastage, improve shelf life, and create additional value for businesses, empowering customers to expand export opportunities. Through innovative machinery and advanced technical expertise, we strive to positively influence customers, industry leaders, and investors, positioning ourselves as change agents revolutionizing the agro-tech sector.

Our mission is to develop world-class food processing machinery and mills with hi-tech, smart, large-scale continuous/batch processing plants for parboiling, drying, steaming, storing, and raw paddy boiling of rice and other grains.

We aim to inspire the next generation of agro-tech businesses by delivering well-engineered, lucrative, and customizable solutions that adapt to changing needs. In a digitally connected world, we stay relevant by continually evolving to meet global industry standards. Our core values are encapsulated by I4C.

Since

Our Products

Revolutionize Your Paddy Process With Photons Foods

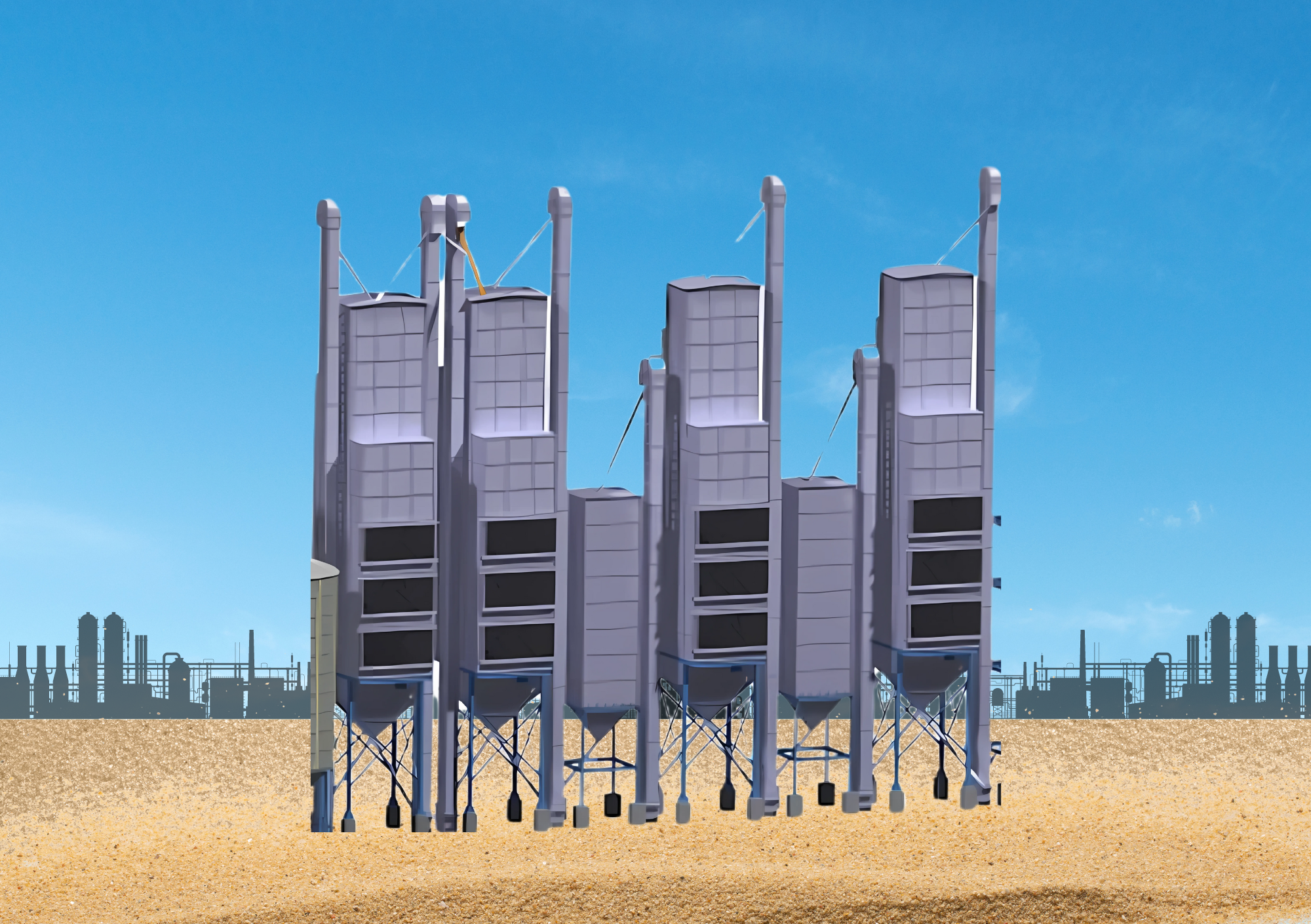

We have been innovating dryer design for over three decades. Suction dryers are stellar best sellers in the recent years. Our trustworthy suction dryers serve large scale production units relentlessly. We have changed the game of drying business by paying close attention and redesigning dryer technologies

Our new and unique parboiling systems was incepted in 1995. There have been multiple successful implementations of these units within India and on a global scale. Our signature methods of continuous par boiling processes ensure homogenous grain output with predictably consistent performance regulated by high standard sensors and PLC controller actuators.

At Photons Foods, our advanced Pre Cooker is designed to optimize the parboiling process in rice milling, ensuring consistent and uniform cooking of rice grains before further processing. Engineered for precision and efficiency, our Pre Cooker shortens the cooking cycle while maintaining the nutritional value and quality of the rice.

We have innovatively introduced software defined controls into our large-scale parboiling and drying systems, as early as 2005. As an active participant in the fourth industrial revolution (Industry 4.0) we pushed automation boundaries via increased machine-to-machine interconnectivity that covers smart automation processes.

We design and implement a 360-degree control dashboard to monitor the entire food processing chain of activities. This enables customers to track, monitor and optimize the production quality and is a valuable analytics tool; the single dashboard helps to keep watch on all key performance indicators (kpi) thus making the system cost efficient.

Our smart factory employs thousands of IoT devices that connect machines and the central dashboard control office to get a clear picture of the manufacturing facility with real-time data. The control center offers a visualization-powered software system. Likewise, we have various kinds of IoT sensors and actuators incorporated into each of the regulatory and monitoring machinery.

The Final Steel Paddy Cooker from Photons Foods is engineered for optimal efficiency in rice parboiling, delivering uniform and high-quality results in large-scale rice milling operations. Built with durable, high-grade steel, this cooker ensures longevity and reliable performance, even under continuous use.

At Photons Foods, our Online Dryers are designed to provide precise and efficient drying solutions for large-scale rice milling operations. With integrated real-time monitoring and smart control systems, these dryers ensure optimal moisture removal, improving the overall quality and shelf life of the rice.

At Photons Foods, our Soaking Tanks are expertly designed to deliver superior soaking performance in rice processing. These tanks ensure even water absorption, preparing paddy for the parboiling process while preserving the grain’s quality and nutritional value.

At Photons Foods, our advanced Automation machines revolutionize rice milling by integrating cutting-edge Industry 4.0 technology. Designed to optimize the entire production process, these machines enable seamless machine-to-machine interconnectivity and smart control systems, ensuring precision, consistency, and efficiency.

Our value

We provide Value to Rice mill owners

Why Choose Us?

Passionately transforming the techo-agro landscape

Photons tackles the toughest challenges in food processing with unmatched expertise, delivering world-class large-scale units that are transforming the tech-agro landscape.

Since 2005, we've integrated software-defined controls into our large-scale parboiling and drying systems, advancing Industry 4.0 with enhanced machine-to-machine interconnectivity and smart automation.

Our 360-degree control dashboard lets customers track, monitor, and optimize the entire food processing chain, providing real-time insights and KPI analytics for improved efficiency and cost savings.

Our smart factory uses thousands of IoT devices to connect machines with the central dashboard, providing real-time data and visualization. IoT sensors and actuators are integrated across all monitoring and control systems.

Photon's dedicated engineers collaborate to achieve excellence in food processing. Our research team ensures high-quality, reliable fabrications, integrating expertise to design and implement cutting-edge machinery.

Some of our Clients