Pneumatic Slide Gates Manufacturers for Smart Grain Handling

- Home

- Pneumatic Slide Gates Manufacturers

Your Trusted Pneumatic Slide Gates Manufacturers for Smart Grain Handling

The food supply of the nation is greatly determined by the ability to move huge amounts of grain. Whether grains are processed into flour, used as raw materials or turned into some other product, many of these foods would not be available in the shops without the right bulk material solutions in place. Grain bulk processing equipment such as rotary airlock feeders, Pneumatic Slide Gate Valve are required to transfer wheat, corn, oats, paddy and various other grains from one point in the production process to the next.

The uneven shape of these grains means that rotary airlock feeders used in the processing of grains must be capable of controlling them smoothly. Also, the coarse nature of several grains and the high -temperature call for extremely durable rotary airlock feeders. Fortunately, Photons has the experience and expertise essential for delivering reliable grain processing equipment to customers in this industry.

What we can offer

Our visionary thinking and technical know-how allow us to craft a diverse range of products for the grain processing industry and Pneumatic Slide Gates are one of them.

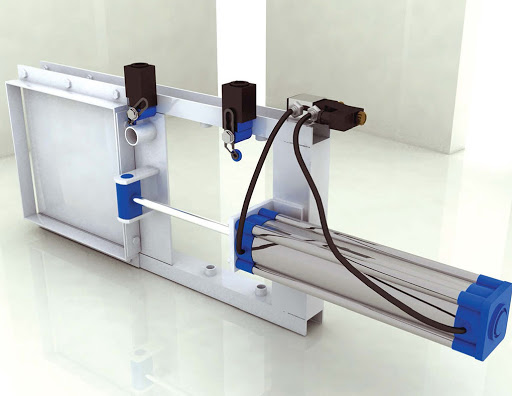

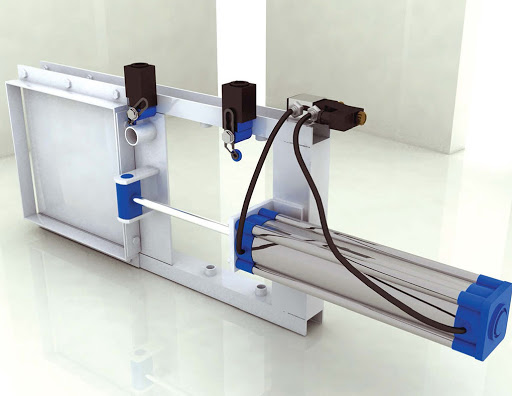

Slide gates provide an efficient way to control the flow of the grain. As the name suggests, it enables a gate to move seamlessly over an opening. As well-known Pneumatic Slide Gates Manufacturers, we at Photons ensure that the material we use is capable of standing up to the toughest conditions.

There are countless industries that need a dependable way to handle the flow of granules, powders or solids from hoppers to other system components. This is where Photon’s Pneumatic Slide Gate Valve become necessary. Their simple design and operating mechanism can easily start or halt the passage of these aggregates and particulates with an extra means to control them. Perfect for dry bulk grain handling, our slide gates are well-built and crafted to separate airlock feeders below from hoppers above. We provide them for gravity feeder systems as fixed fixtures or as maintenance valves for isolating parts for repair. In either case, the bulk material slide gate parts are built with the same dedication to quality and robustness as the rest of our equipment.

Our visionary thinking and technical know-how allow us to craft a diverse range of products for the grain processing industry and Pneumatic Slide Gates are one of them.

Slide gates provide an efficient way to control the flow of the grain. As the name suggests, it enables a gate to move seamlessly over an opening. As well-known Pneumatic Slide Gates Manufacturers, we at Photons ensure that the material we use is capable of standing up to the toughest conditions.

There are countless industries that need a dependable way to handle the flow of granules, powders or solids from hoppers to other system components. This is where Photon’s Pneumatic Slide Gate Valve become necessary. Their simple design and operating mechanism can easily start or halt the passage of these aggregates and particulates with an extra means to control them. Perfect for dry bulk grain handling, our slide gates are well-built and crafted to separate airlock feeders below from hoppers above. We provide them for gravity feeder systems as fixed fixtures or as maintenance valves for isolating parts for repair. In either case, the bulk material slide gate parts are built with the same dedication to quality and robustness as the rest of our equipment.

Constructed using heavy-duty steel which adds to the dependability and durability, these slide gates offer various benefits usually not found in ordinary slide gates. They are also completely dust-free and therefore don’t require caulking during installation. Moreover, they are easy to operate and can seamlessly fit onto virtually any sized flanges.

Known as one of the leading Pneumatic Slide Gates Manufacturers in the industry, we believe in offering the best bulk material handling solutions with quality like on other. With our assistance, your business can get a tailored solution that perfectly meets your needs. To find out how we can boost your operations, get in touch with us today!

Our vision is to provide state-of-the-art technology, large scale, smart and fully automated food processing machinery to modernise agro-tech industry.

Through our vision, we aspire to deliver best-of-its-class parboiling and drying machinery alongside installation of rice and granary mills all over the world. We strive to serve the food processing industry by constantly thriving to reduce wastage, improve shelf life, and create additional produces for more business value. We believe this will create surplus of opportunities for customers to export. We achieve this by our innovative modern machinery and advanced technical acumen. We influence our customers, industry decision makers, and investors in a positive manner. We see ourselves as change agents revolutionising the agro-tech industry.

Our mission is to develop world-class food processing machinery and mills through hi-tech, smart, large scale, continuous/batch processing plants for parboiling, drying, steaming, storing, and raw paddy boiling of rice and other grains.

Through our mission, we seek to develop and inspire the next generation of agro-tech business that remains well engineered, lucrative, and customizable for changing business needs. We remain relevant in a digitally shrunk world by continually evolving our offerings to meet the world-class industry standards. Our core values can be abbreviated as I4C