The Advanced Rice Dryer Machine

- Home

- The Advanced Rice Dryer Machine

The Advanced Rice Dryer Machine: The Revolutionary Way to Dry Paddy

During the time of harvest, the content of moisture in rice ranges between 18-25%. After the harvest, the most complex process is paddy drying. Drying decreases the moisture content in the paddy which is required for safe storage. The quality of the grain is greatly determined by the way grains are looked after during the drying and storage process. Any delay in the process of drying can reduce the quality. Storing moist grain can result in its discolouration or encourage mould development. It further increases the chances of pest attacks regardless of how well they are stored. And that is why it is important to have an innovative Rice Dryer Machine that can quickly and efficiently dry paddy and ensure a sustainable outcome.

The benefit of grain drying using modern technology

Safe storage: With reduced moisture, the possibility of deterioration or germination of the cereal gets eliminated, allowing safer storage for longer periods.

Lesser moulds: Less amount of water content also reduces the risk of mould production. Moulds are responsible for degrading the cereal that can eventually cause harm to everyone’s health.

Less wastage: With the least possibility of grain damage, the chances of any possible wastage also become way lesser.

Better quality and productivity: Grain drying using innovative methods enables a fast process and greater productivity, removing the risks associated with product damage.

Greater revenue: The better quality of cereals allows farmers to sell the product at higher prices thus maximizing their revenue.

The benefit of grain drying using modern technology

Safe storage: With reduced moisture, the possibility of deterioration or germination of the cereal gets eliminated, allowing safer storage for longer periods.

Lesser moulds: Less amount of water content also reduces the risk of mould production. Moulds are responsible for degrading the cereal that can eventually cause harm to everyone’s health.

Less wastage: With the least possibility of grain damage, the chances of any possible wastage also become way lesser.

Better quality and productivity: Grain drying using innovative methods enables a fast process and greater productivity, removing the risks associated with product damage.

Greater revenue: The better quality of cereals allows farmers to sell the product at higher prices thus maximizing their revenue.

The Highly Advanced Paddy Drying System from Photons

In the traditional methods of drying such as sun-drying and field-drying, farmers have to leave their harvested produce on the field or concrete floor for several hours and even days to expose them to the sun’s heat. It is a time-taking process which also depends on the weather conditions. Sudden weather changes, such as rain or fog can obstruct the drying process. This may lead to delayed drying, re-wetted paddy or quality degradation which eventually reduces the market value of the grain.

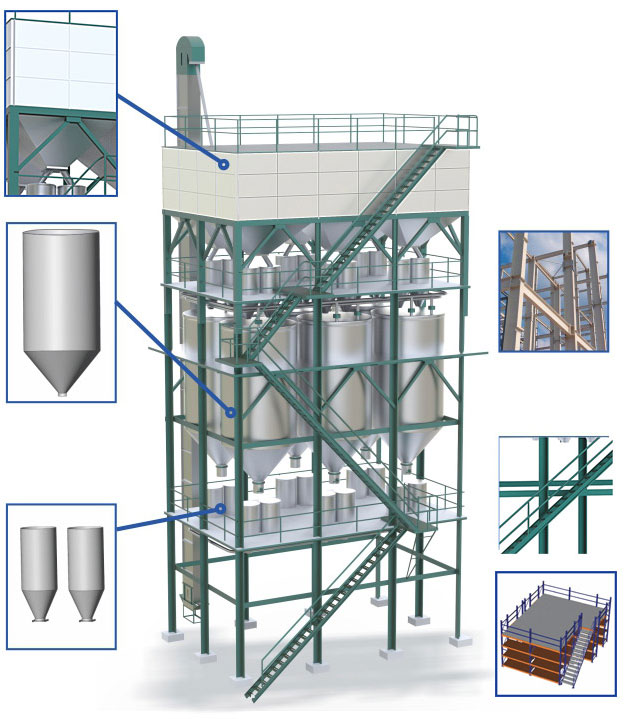

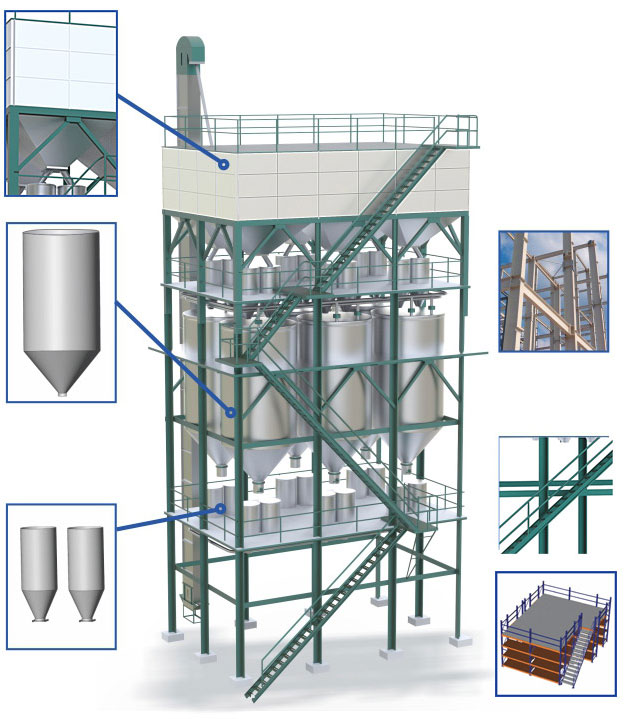

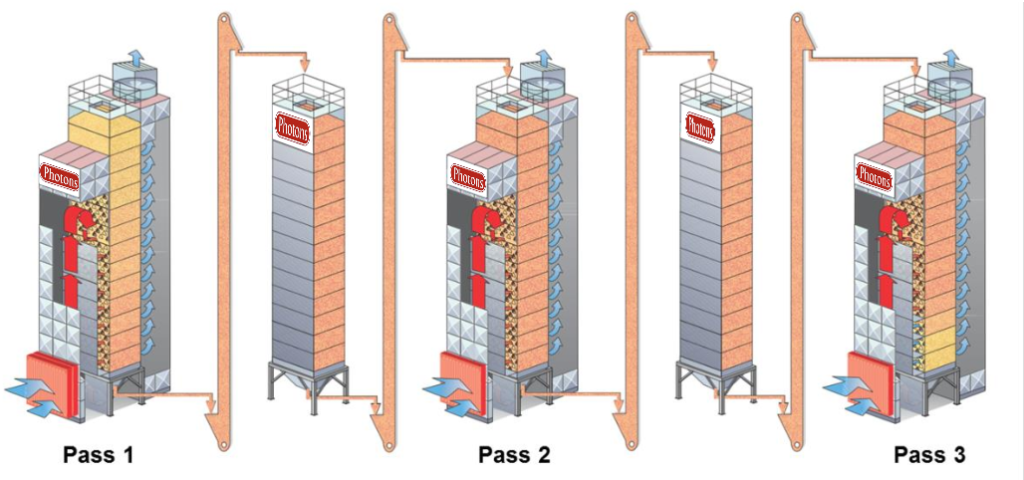

Therefore, to overcome this challenge, Photons came up with an advanced solution in the form of suction dryers and various other highly innovative and modern Rice Mill Dryer machines made up of stainless steel that are equipped with blowers and digitalized monitor system to control the temperature of the air during the drying process. Apart from ensuring rapid and effective drying method, the machine is designed to provide even steaming for maintaining the quality of the paddy grains.

At Photons, we have been advancing our techniques of creating dryer designs for over three decades. Our suction dryers are the best sellers in recent times due to their ability to serve large-scale production units seamlessly. We have reinvented the way businesses operate in the grain processing industry with our unique technological advancements and creativity that cater to the needs of the people of today.

Our vision is to provide state-of-the-art technology, large scale, smart and fully automated food processing machinery to modernise agro-tech industry.

Through our vision, we aspire to deliver best-of-its-class parboiling and drying machinery alongside installation of rice and granary mills all over the world. We strive to serve the food processing industry by constantly thriving to reduce wastage, improve shelf life, and create additional produces for more business value. We believe this will create surplus of opportunities for customers to export. We achieve this by our innovative modern machinery and advanced technical acumen. We influence our customers, industry decision makers, and investors in a positive manner. We see ourselves as change agents revolutionising the agro-tech industry.

Our mission is to develop world-class food processing machinery and mills through hi-tech, smart, large scale, continuous/batch processing plants for parboiling, drying, steaming, storing, and raw paddy boiling of rice and other grains.

Through our mission, we seek to develop and inspire the next generation of agro-tech business that remains well engineered, lucrative, and customizable for changing business needs. We remain relevant in a digitally shrunk world by continually evolving our offerings to meet the world-class industry standards. Our core values can be abbreviated as I4C